Reuters had an interesting article (which it recently pulled) about two companies that are working together to make algal biofuels.

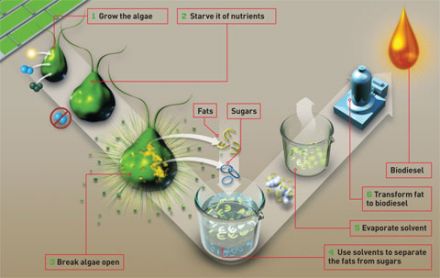

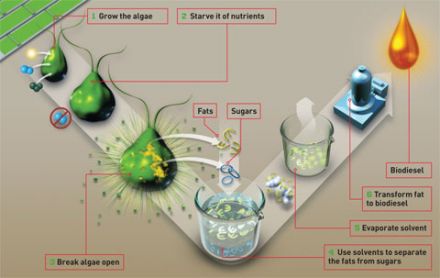

Algae, which uses sunlight and nutrients commonly found in standing waster to grow, naturally produces a small amount of oil. The amount of oil produced can be increased by various techniques and companies like Solazyme and BlueFire hope to produce enough oil to start to replace transportation fossil fuels. The video below covers the basics of the algal biofuel production process.

Algal biofuels have been getting a lot of buzz recently and there is definitely a lot of potential for algae in the alternative fuel domain. Algae can be grown in salt water, and therefore doesn’t require fresh water – a resource that is becoming more precious. Unlike corn and other potential biofuel feedstocks, people don’t rely on algae as a major food source. Algae is very hearty and can survive in a variety of different climates. Although these and many other features of algae make it very attractive for alternative fuel research, there are hurdles facing algae researchers.

The biggest problem is that algae biofuels, sometimes called oilgae, are still too expensive to make. Even though algae can double in mass in just a few hours, the current known algae strains don’t produce enough oil for the overall process to be economically competitive with fossil fuels. Solazyme and BlueFire propose to solve the production problem by feeding the algae non-food sugars, a process which they claim is “1000 times more efficient” than the algae using just sunlight to produce oil.

The duo plans to convert what they’re calling non-food “green waste” into sugars that they then feed to the algae to produce oil. The BlueFire website says that examples of green waste include “leaves, grass clippings, vegetable and fruit wastes.” This process converts the starch in these organic wastes into sugars which can then be fed to the algae. Taking a waste stream, like non-food organic waste that would end up in a landfill, and turning it into a fuel is a fantastic idea.

There are a few big problems however. One is that the facility requires a lot of acid – which can not only get expensive, but can have environmental impacts during both the production of the fresh acid and disposal of the spent acid. The bigger problem in my eyes, however, is the availability of green waste.

While it’s true that millions of acres are mowed every day in the US and that millions of banana peels end up in the dump, collecting and transporting these organics from their source to the proposed facility will be a huge challenge. It’s a challenge to encourage people to turn lights off when they leave a room. Imagine what it will take to get people to throw organics into a special garbage bin instead of their normal trash or recycling. Do local cities collect the green waste or do households have to take the organics to a central facility? How will contaminants be minimized and handled?

Another issue is the scale. While I realize that the proposed plant is the first of its kind, a 4 million gallon/year facility will produce less than 1.5% of a single day’s gasoline production in the states. That’s 0.0028% of the annual gasoline production compared to the June 2007 high of 9.3 million barrels of gasoline produced per day.

Finally, is this process in energy balance? In other words, does it use more energy than it produces? Corn ethanol has this – and other – problems. The production of ethanol by fermenting the sugars in corn requires a lot of energy. Large amounts of natural gas are required to make the fertilizer that is necessary for corn to grow and separating the ethanol from the water in the process is also very energy intensive. The energy balance for corn ethanol is still being debated but what’s clear already is that corn ethanol is forever tied to fossil fuels for nutrients, harvesting, and processing. Is the same true for Solazyme and BlueFire’s process?

Bottom Line: Algal biofuels have a lot of potential but also a long way to go. If Solazyme and BlueFire can find answers to some of these hurdles, they’ll not only make a lot of money doing it, but help change the world for the better.

http://www.reuters.com/article/mnEnergy/idUS304085936320090527